Fall kick-off ylab news backlog: Desktop Metalwork

Ylab’s metal master

Ylab’s hosts at the David Dunlap Observatory have a nice simple reception desk – but they want the ability to lock up whatever is on top. You know, big things than won’t fit in a drawer. Which is kind of impractical because there are no drawers on the desk. They asked us if we could do something about it. We like a challenge. We put ylab member Metal Master Miro to work on it.

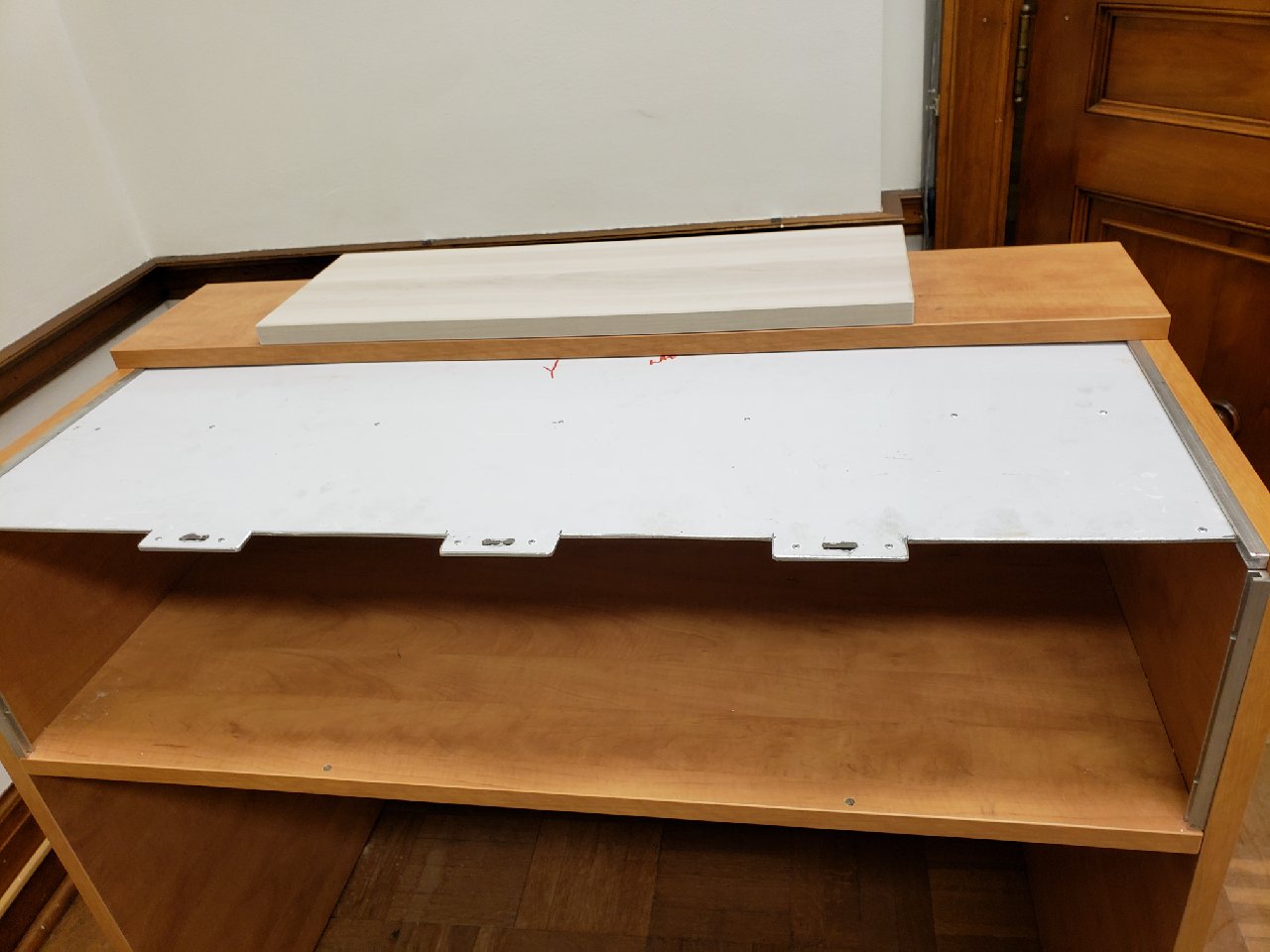

Aluminum panels can cover the opening, but they need support. The requirement is to make them removable and have them discretely stored.

We started with some solid 1/4” square aluminum bars. We milled a channel on the aluminum to hold the panels, and drilled and countersunk holes for the mounting screws.

Then we worked the panels. Aluminum sheets in the thickness we use is not quite rigid enough for the span, so we made reinforcement bars and riveted them to the sheets.

For all the pieces, a copious amount of filing and elbow grease was required to soften up rough edges.

We made and mounted supports for discretely storing the panels when not in use.

And finally, it all goes together in four simple steps.

Just add padlock. We’ll take off the protective plastic layer and clear coat it after it’s been inspected.

And with all the milling, drilling and filing, we got our money’s worth out of this guy.

- A.I. North and Python (2)

- Announcements (60)

- Events (88)

- Post-Event Report (25)

- Radio (9)

- Robotycs (5)

- Uncategorized (11)

- Upcoming Event (9)

- Update (32)

Latest Articles

YLab

123 Hillsview Dr, Richmond Hill, ON L4C 1T3